Stevie can i make a dumb question ,stevieturbo wrote:If the engine runs, you can log, it is always logging....dont understand why you say you cant log ?

In theory yes, you could adjust the main table 50kpa -50% etc etc and that should be the same thing. Then set compensations to zero.

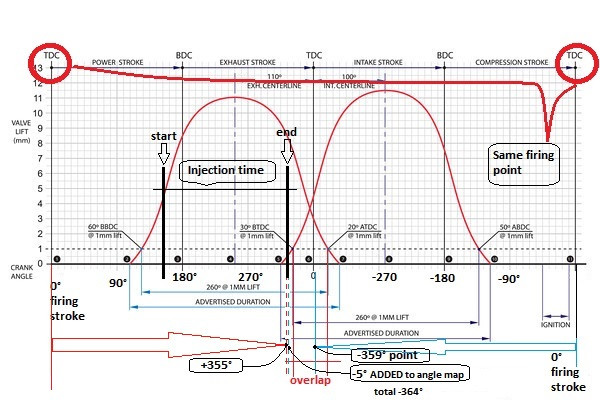

I would agree about injecting against a closed valve, that does seem to be the opinion of what is best. Not sure what actual number this is on the DTA though, or where they reference zero to. Most likely TDC Cyl 1 ?

Just open the throttle blade with the adjustment screw ? Or bend the closed stop a little.

I see no reason to be dropping idle timing much lower than 8-9 deg anyway.

As you lean the mixture from 13.2, idle speed will likely drop anyway

How the electronic unit understand that the engine is running?

Is it the " transition from cranking " from General Engine Settings table ?

Because you insist that if engine is running, then ECU can Log, the running engine .

__________________________________________________

Ok , i wanted a simple confirmation, i 'll put the theory into practice .

__________________________________________________

I belive so but better I'll ask Alan About it.

__________________________________________________

As you lean the mixture from 13.2, idle speed will likely drop anyway

For sure, this is going to be but i'll let more air to get into the engine and gain back the idle .

Nop, there is nothing to bend as it is a solid block of aluminium .

The only, i think for me to do is to drill the closed throttle stop and place a bolt 'n nut pusching the throttle .

Of course i have to relearn of throttle stops in ecu and all function related to throttle and every time after .